Straight-line Wire Drawing Machine

Machine Introduction and Video

| Machine model | GT2-4H | GT3-8H | GT6-12H | GT10-16H |

| Wire thickness | 2-4mm | 3-8mm | 6-12mm | 10-16mm |

| Cutting length | 0.7-12M | 0.5-12M | 1-12M | 1-12M |

| Working speed | 40-100M/min | Max.120M/min | Max.130M/min | Max.130M/min |

| Straight motor | 1.5kw | 11kw | 37kw | 45kw |

| Cutting motor | 1.5kw | 3kw (servo motor) | 7.5kw (servo motor) | 7.5kw (servo motor) |

| Cutting accuracy | ±0.5mm | ±2mm | ≤ 2mm/m | ≤ 2mm/m |

| Machine weight | 700KGS | 2000KGS | 4700KGS | 5500KGS |

Machine Description

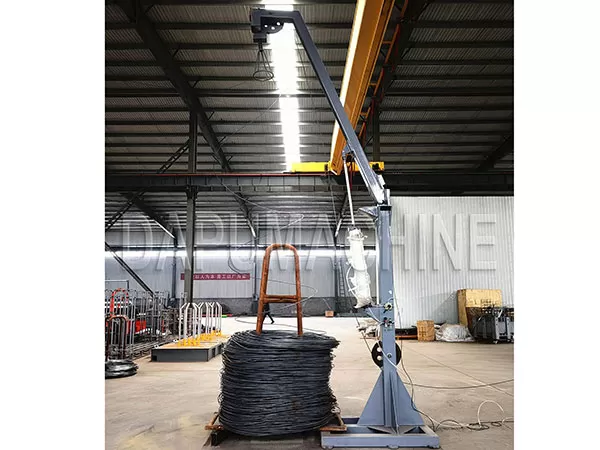

Hydraulic pay-off: used to load and feed the wire material

Mechanical sheller: used to clean steel rust and oxide coating on wire surface

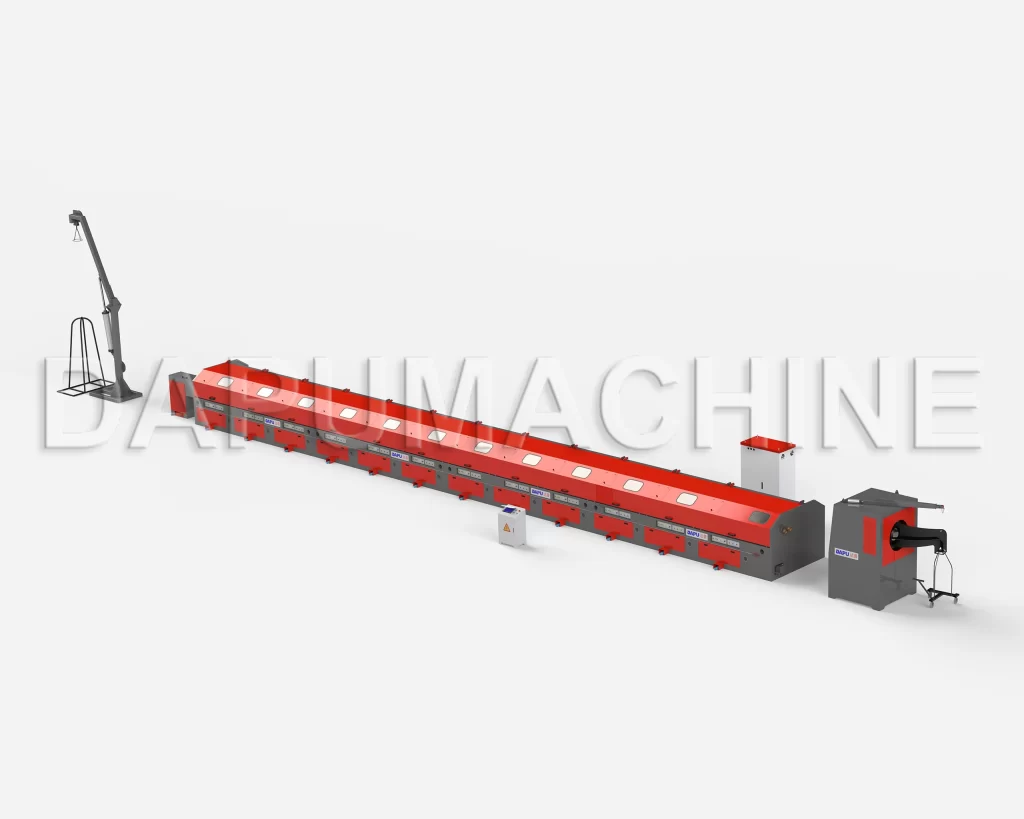

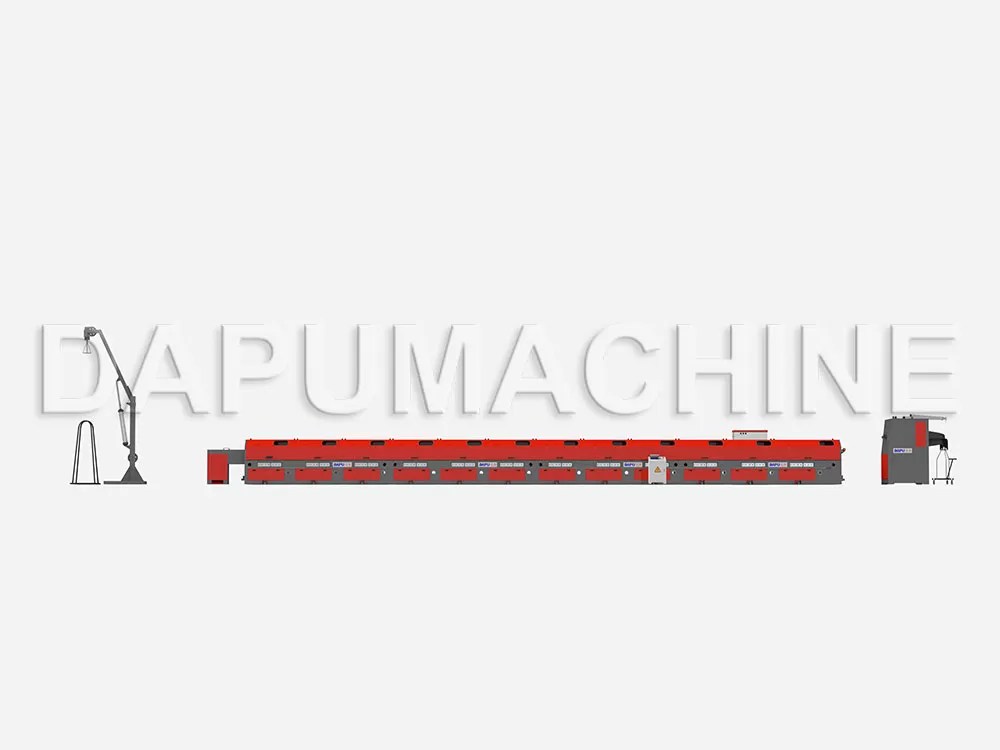

DP-LZ-560 wire drawing machine: the number of drawing pots depends on the wire size you want

Elephant nose take-up or I-wheel take-up: used to load the finished wire.

Straight-line Wire Drawing Machine Technical Parameters

| Model | DP-LZ-560 |

| Raw material | low/medium/high carbon steel wire, stainless steel wire |

| Input wire thickness | 8.0mm, 6.5mm, 6.0mm, 5.5mm etc. |

| Output wire thickness | 3mm, 2.5mm, 2.2mm, 2.0mm, 1.8mm, 1.6mmm etc. |

| Each motor capacity | 37kw, 30kw, 22kw (design as your wire thickness and tensile strength) |

| Drawing speed | Max. 16-18M/min |

| Weight | 2000KGS/each drawing pot |

| Model | DP-GW-2500B |

| Wire diameter | 4-12mm |

| Line wire spacing | 100-250mm |

| Cross wire spacing | 50-300mm |

| Mesh welding width | Max.2500mm/3000mm |

| Mesh length | Max.6m/12m |

| Welding points | 24pcs/30pcs |

| Welding speed | Max.80-100 times/min |

DP-LZ-560 Wire Drawing Machine Description

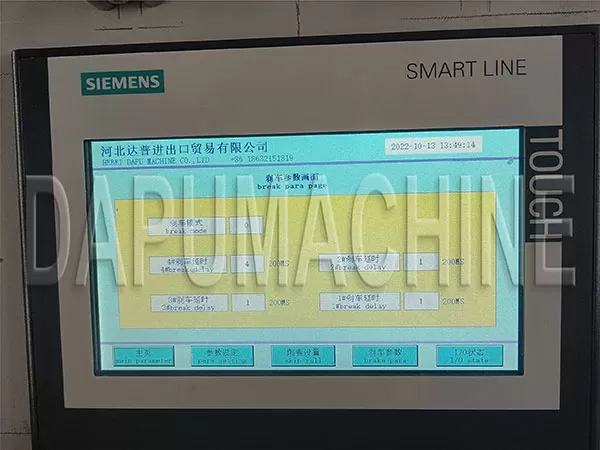

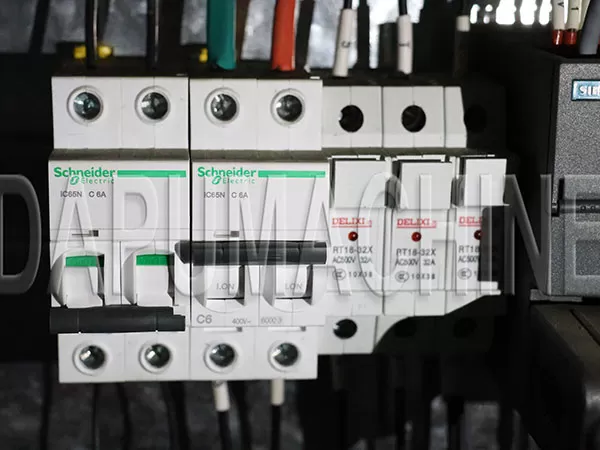

Electric control cabinet: components are all world-famous brand

Siemens PLC+touch screen

Schneider power supply/contractor/breaker

ABB motor/inverter

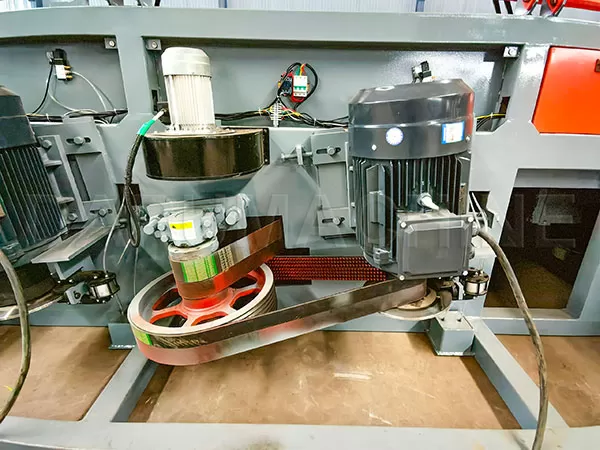

Reducer & V-belt control the drawing pots, so low maintenance and working stable

The drawing blocks are made steel cast. Supersonic tungsten carbide spray on the block surface.

Water cooling system inside of the block to reduce the working temperature.

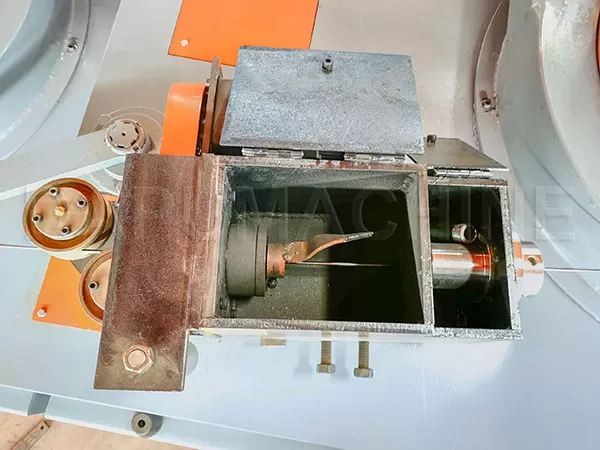

Rotating mold box, extend life of the wire drawing die and the finished wire will be more round.

After-sales Service

Installation and commissioning: Our engineer can go to your factory to install and commission the equipment to ensure the normal operation of the equipment.

Technical training: We will provide detailed operation and maintenance training book to enable your employees to operate the equipment proficiently.

24-hour online service: Reply your message timely when you have question on the machine.

Spare parts supply: Ensure to supply the original spare parts.

FAQ

Q: How many drawing pots do I need for the machine?

A: It depends on the input wire diameter and output wire diameter you want.

Q: What raw material are suitable for the machine?

A: Our machine is suitable for low/middle/high carbon steel wire.

Q: Can we make the finished wire with ribs?

A: Yes, we can add ribbed device on the machine. So finished wire will be with ribs.

Q: What maintenance is required for the machine?

A: Regular maintenance includes cleaning and inspecting the dies, checking the lubrication system, and ensuring all mechanical parts are in good condition.