358 anti-climb mesh welding machine

Machine Introduction and Video

| Model | DP-FP-3200A+ |

| Working speed | Max.120times/min |

| Wire thickness | 3-6mm |

| Line wire space | 76.2-300mm/75-300mm |

| Cross wire space | Min.12.7mm/12.5mm |

| Mesh width | Max.3200mm |

| Mesh length | Max. 6000mm |

| Welding points | 44pcs |

| Welding transformer | 150kva*11pcs |

| Line wire feeding way | Pre-straighten & pre-cut, then fed with wire feeding car |

| Cross wire feeding way | Pre-straighten & pre-cut, then fed from hopper device |

| Weight | 5.3T |

Machine Advantage

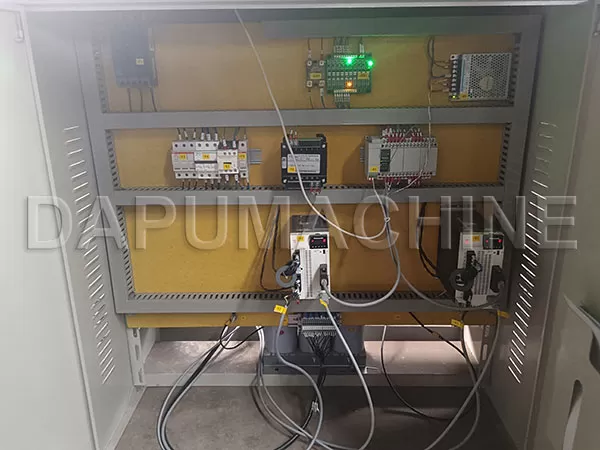

Electric control cabinet: components are all world-famous brand, promise the machine can work stable and long life.

Panasonic (Japan) PLC

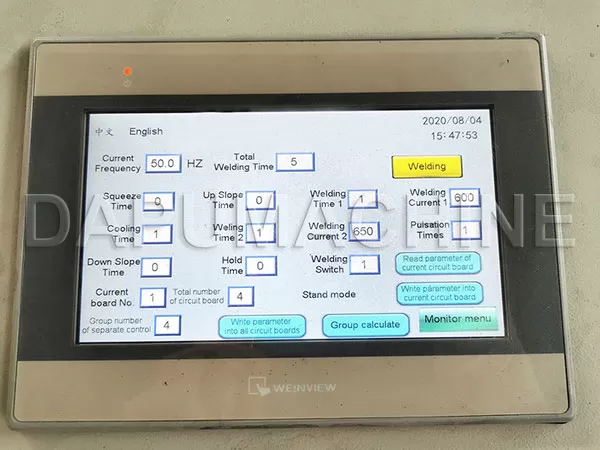

Weinview (Taiwan) touch screen

Schneider (France)

ABB (Switzerland) switch

Delta (Taiwan) power supply

Panasonic (Japan) servo drive

One SMC air cylinder control one welding points so the welding pressure on each point will be same. The finished mesh will be more flatten.

Upper copper wires connect the welding electrodes directly so the welding points part will be more solid.

Water cooling technology adopted on welding electrodes and transformer can reduce temperature when machine working. Then the machine can work stable.

European design line wire feeding device, can feed the line wires more accurate, save the labor and easy to operate.

Auxiliary Equipment

Wire straightening and cutting machine GT3-6H: used to pre-straighten & pre-cut the line wires and cross wires.

Fence mesh welding machine: used to bend the panel mesh with 3D bender.

After-sales Service

Installation and commissioning: Our engineer can go to your factory to install and commission the equipment to ensure the normal operation of the equipment.

Technical training: We will provide detailed operation and maintenance training book to enable your employees to operate the equipment proficiently.

24-hour online service: Reply your message timely when you have question on the machine.

Spare parts supply: Ensure to supply the original spare parts.

FAQ

Q: How many containers for loading the machine?

A: One 40 feet container for the main mesh welding machine; If you want to complete production line with auxiliary equipment, will need two 40 feet containers.

Q: How to adjust the mesh opening size?

A: Move the welding electrode to adjust the line wire space; cross wire space can be set on the touch screen.

Q: What maintenance is required for the machine?

A: The sliding parts of the machine should be oiled once a week.

The machine needs to be cleaned of welding slag with an air gun once a day.

Anti climbing finished product