Chicken cage welding machine

Machine Specification and Video

| Model | DP-AW-1200H | DP-AW-1200H+ |

| Wire diameter | 2-4mm | 2-4mm |

| Line wire space | 50-200mm | 2-3mm, 25-200mm

3-4mm, 50-200mm |

| Cross wire space | 12.5-200mm | 12.5-200mm |

| Mesh width | Max. 1200mm | Max. 1200mm |

| Welding points | 25pcs | 49pcs |

| Aire cylinder | 25pcs | 17pcs |

| Welding transformer | 125kva*3pcs | 125kva*5pcs |

| Welding speed | Max.130-150times/min | Max.120-150times/min |

| Line wire feeding way | From wire coils automatically | |

| Cross wire feeding way | Pre straighten & cut, feed from hopper | |

Machine Advantage

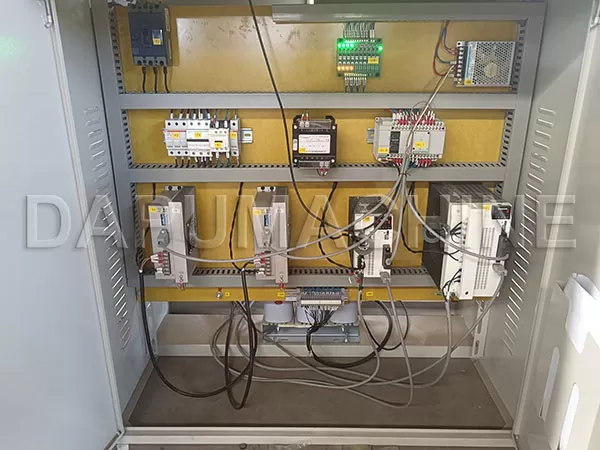

Electrical control box: Panasonic, ABB, Schneider etc. components, promise the machine working stable.

Crosswire feeding & falling control by step motor & air cylinder. Single and double cross wire hopper can be designed as you want.

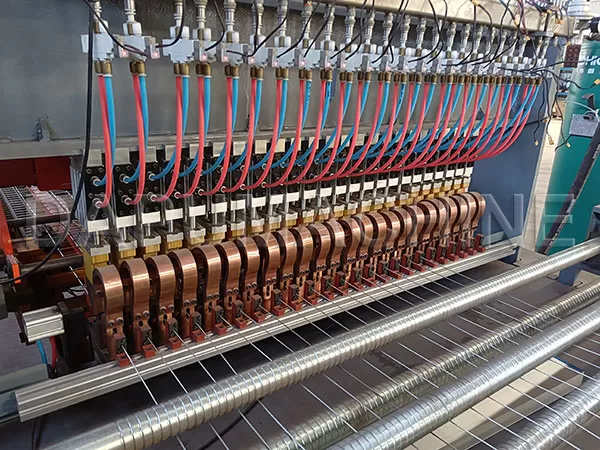

European welding technology: upper welding electrode connect the lower electrode base directly and one SMC air cylinder control one welding point. Promise the welding current and pressure can be on the welding points only, so the finished panel mesh will be more flatten.

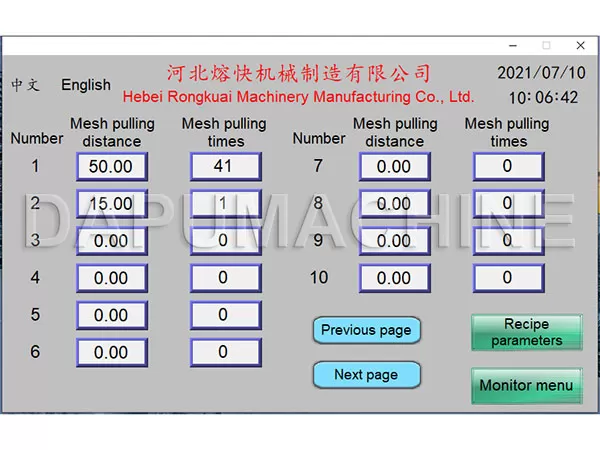

Panasonic servo motor control the mesh pulling. Finished mesh can be cut and falling down automatically.

Auxiliary Equipment to make cages

1.Cage bending machine

2.Door digging machine

3.Edge cutting machine

4.Electric cutter

After-sales Service

Installation and commissioning: Our engineer can go to your factory to install and commission the equipment to ensure the normal operation of the equipment.

Technical training: We will provide detailed operation and maintenance training book to enable your employees to operate the equipment proficiently.

24-hour online service: Reply your message timely when you have question on the machine.

Spare parts supply: Ensure to supply the original spare parts.

FAQ

Q: How to set the mesh length of the machine?

A: The mesh length can be set on the touch screen.

Q: Can I know the payment terms of your company?

A: 30%T/T in advance, 70% by T/T before machine loading.

Q: Can you make the machine as our local voltage?

A: Yes, we can make the voltage as your requirements.

Q: Delivery time of the machine?

A: 40 days after receiving the advance payment.

Q: What maintenance is required for the machine?

A: The sliding parts of the machine should be oiled once a week.

The machine needs to be cleaned of welding slag with an air gun once a day.

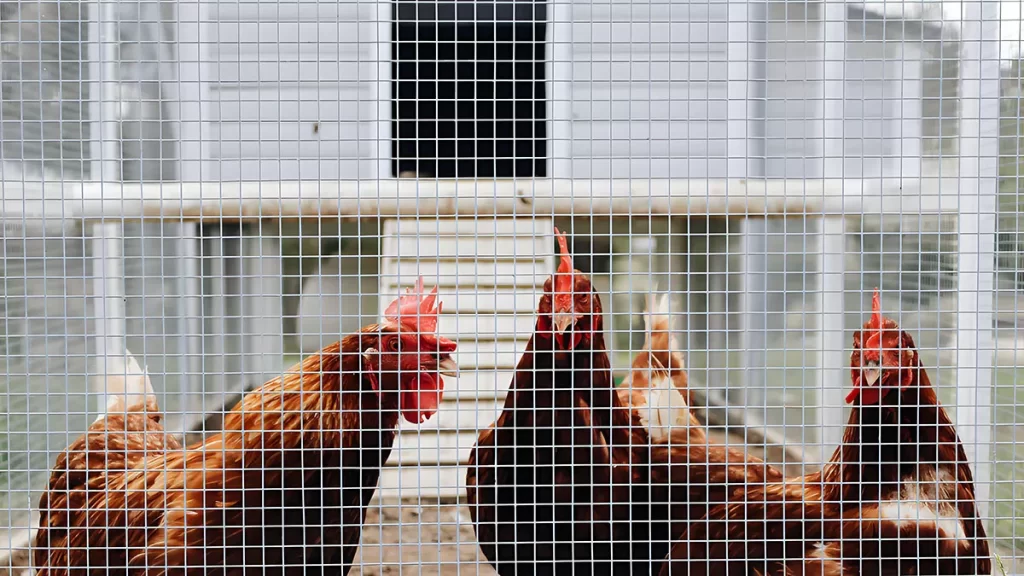

Finished Product