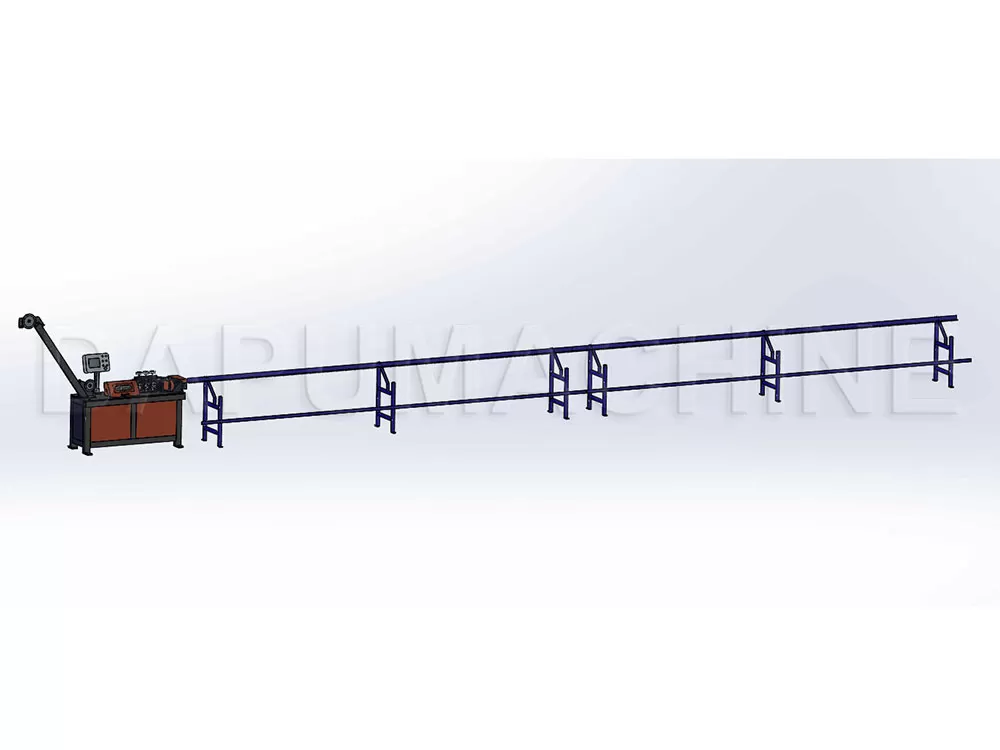

High Speed Wire Straightening and cutting Machine

Machine Specification and Video

| Machine model | GT2-4H | GT3-8H | GT6-12H | GT10-16H |

| Wire thickness | 2-4mm | 3-8mm | 6-12mm | 10-16mm |

| Cutting length | 0.7-12M | 0.5-12M | 1-12M | 1-12M |

| Working speed | 40-100M/min | Max.120M/min | Max.130M/min | Max.130M/min |

| Straight motor | 1.5kw | 11kw | 37kw | 45kw |

| Cutting motor | 1.5kw | 3kw (servo motor) | 7.5kw (servo motor) | 7.5kw (servo motor) |

| Cutting accuracy | ±0.5mm | ±2mm | ≤ 2mm/m | ≤ 2mm/m |

| Machine weight | 700KGS | 2000KGS | 4700KGS | 5500KGS |

Machine Description

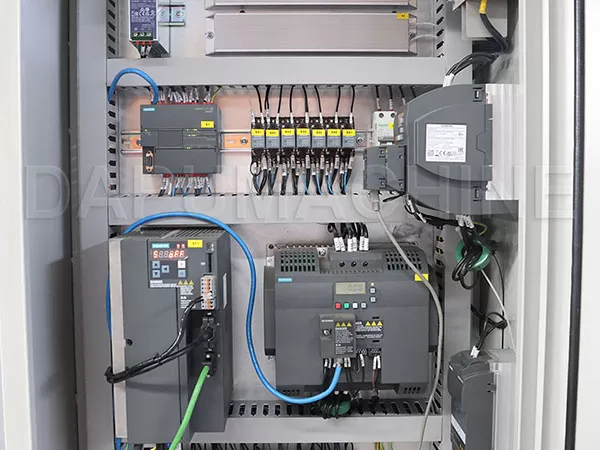

Electric control cabinet: components are all world-famous brand.

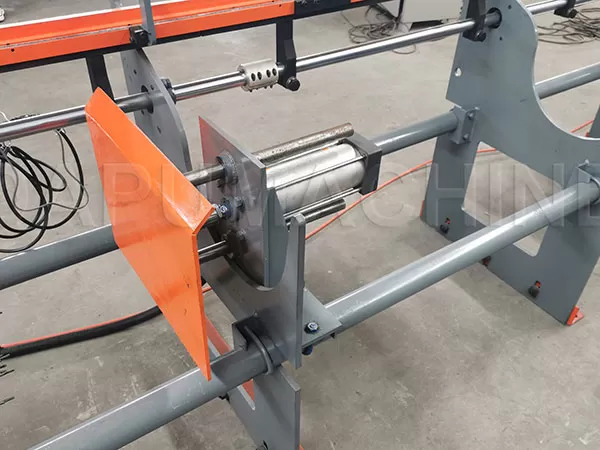

Designed straightening tube with alloy steel straightening mold

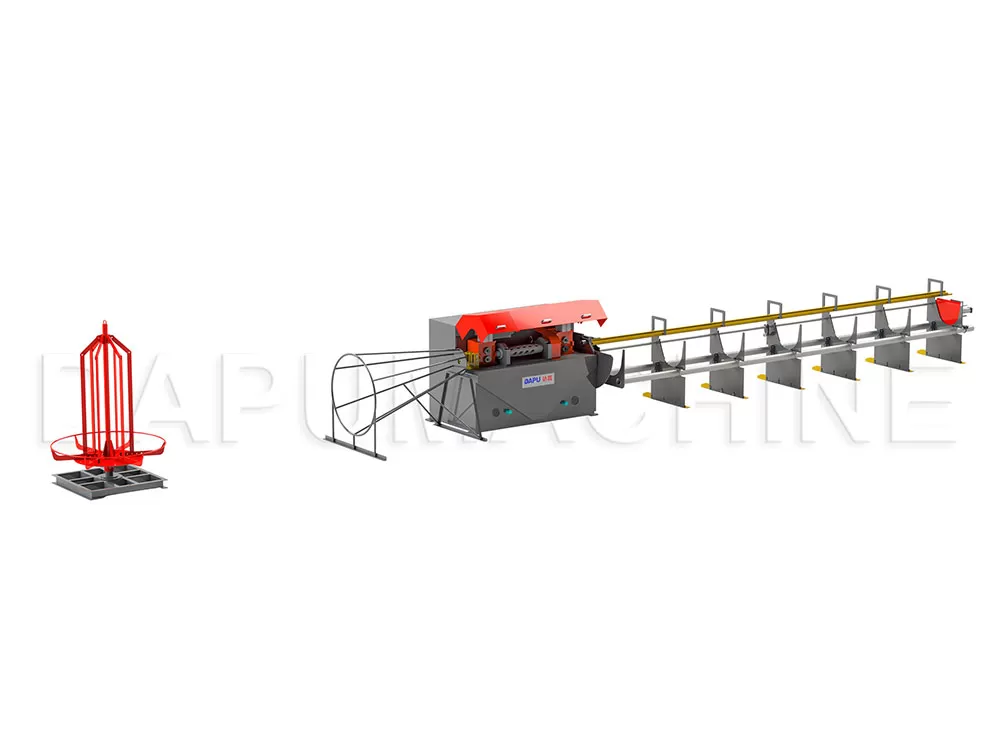

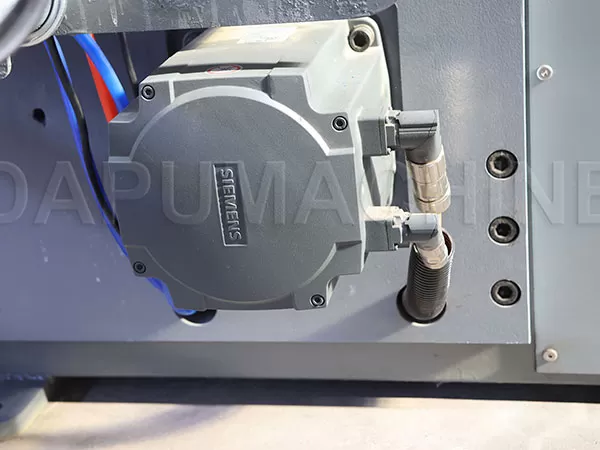

Siemens servo motor control the finished wire cutting

Wire falling bracket with pneumatic device and wire pushing device

After-sales Service

Installation and commissioning: Our engineer can go to your factory to install and commission the equipment to ensure the normal operation of the equipment.

Technical training: We will provide detailed operation and maintenance training book to enable your employees to operate the equipment proficiently.

24-hour online service: Reply your message timely when you have question on the machine.

Spare parts supply: Ensure to supply the original spare parts.

FAQ

Q: What raw material are suitable for the machine?

A: Our machine is suitable for cold/hot round/ribs wire or galvanized wire.

Q: If we can make the touch screen with our language.

A: Yes, we can make the touch screen with the language you want, Chinese, English, Russia, Spanish, Portuguese etc.

Q: How to load the machine? In the full container or less container?

A: Depends on the type and quantity you want. One set GT2-4H machine need be loaded in the wooden box; One set GT3-8H machine need one 20 feet container.

Q: What maintenance is required for the machine?

A: Clean the dust under the conveyor wheel and straightening roller every day.